Symbiosis is delighted to announce an expansion of its capabilities to handle novel and emerging treatments, such as viral based gene- and oncolytic-therapies

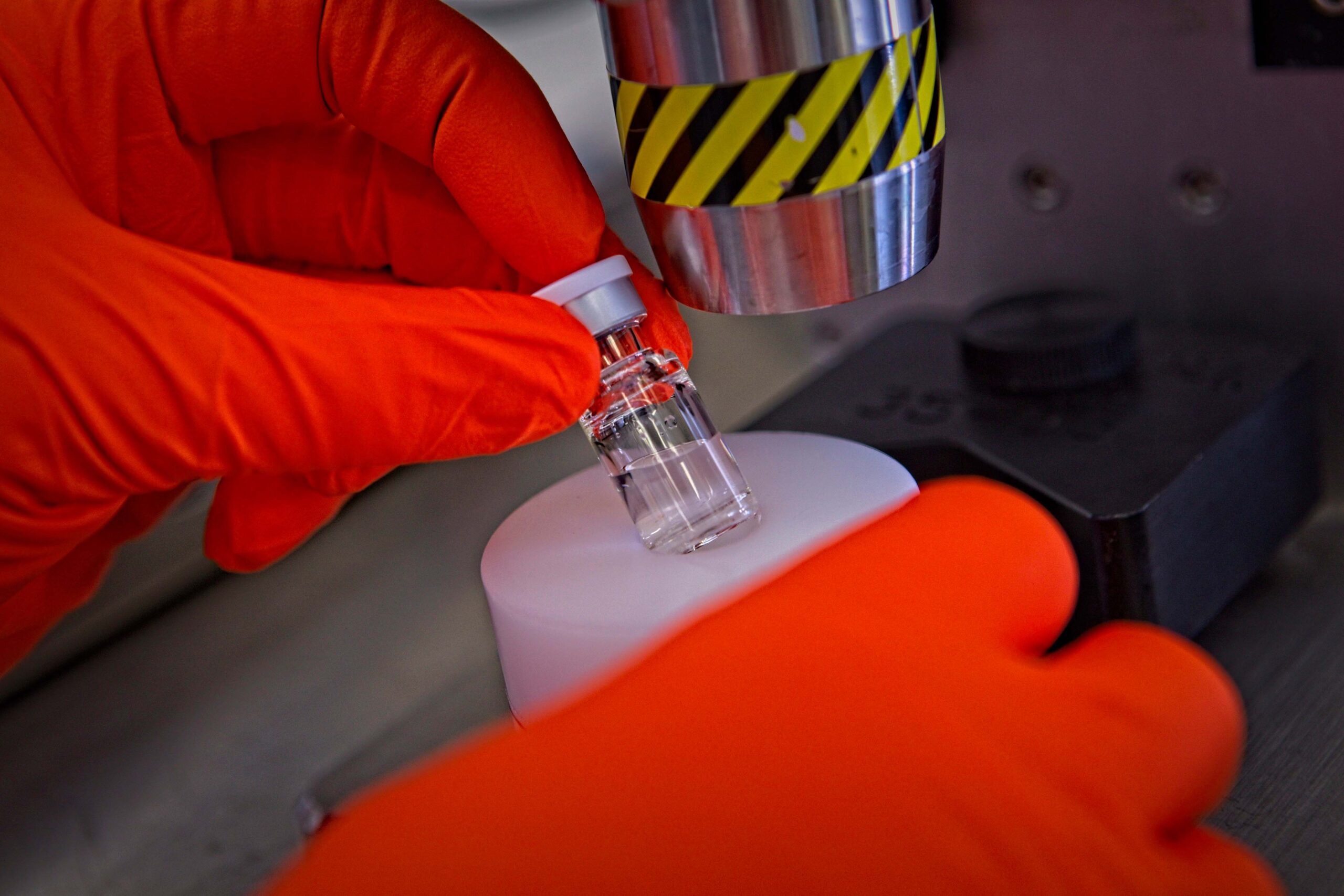

Headquartered in Stirling, UK, Symbiosis has completed a physical and regulatory upgrade to its existing manufacturing suites to enable the safe manufacture of biopharmaceutical products which require biosafety level 2 (BSL-2) handling. This allows Symbiosis to meet the needs of the rapidly expanding viral vector cell and gene therapy market and allow for greater flexibility in the way existing and novel products can be handled.

“We have been very busy over the past year with upgrades to our existing facilities as well as preparing the ground for expansion which will continue over the next 12 to 18 months” Colin MacKay, CEO of Symbiosis said: “Expanding our manufacturing capability to BSL-2 is really just the latest effort in what has been a sustained investment in the business and its people over the past 10 years”.

Symbiosis has extensive experience in the manufacture of Advanced Therapeutic Medicinal Products (ATMPs), including viral vectors for cell and gene therapy use, delivering dozens of batches to date. These viral-based technologies translate into therapies which can provide a curative treatment route for previously intractable conditions, including heritable genetic disease as well as cancer.

John McCormick, COO of Symbiosis added: “By adding new capabilities such as BSL-2 we are much better placed to meet the increasingly complex demands of the emerging therapies market. A high proportion of these viral therapies target small patient populations, and thus require a much smaller scale production volume than traditional CMOs can offer. Symbiosis is perfectly placed to meet that need.”

Colin MacKay concluded: “The increasing complexity of these products as well as the growth in demand we have seen in our target markets underpins the continued investment in our manufacturing infrastructure. Our total facilities footprint is now over 30,000 sq ft, which can comfortably accommodate both our people and our client’s projects for the next few years with room for further increases in manufacturing output.”

In support of this new capability Symbiosis has made available a technical note entitled ‘Biosafety level considerations in biologic manufacturing and aseptic filling of ATMPs’ which outlines the general considerations for biological containment in manufacturing of biologics. For a copy of this technical note, please email contact@symbiosis-pharma.com