Symbiosis supports the GMP aseptic viral vector manufacturing complemented with manufacture of critical raw materials, including plasmids for Advanced Therapeutic Medicinal Products (ATMPs).

ATMPs (Advanced Therapy Medicinal Products) are human therapeutics with mechanisms of action based on treatment at the genetic, cellular or tissue level. They provide new strategies and treatment regimens for the treatment of rare (and orphan) diseases and critical conditions.

Symbiosis has supported clients by sterile filling vectors, plasmids and oligonucleotide products for in vivo and ex vivo gene therapy for the transduction of somatic autologous cells and for adaptive cell therapies.

The range and type of ATMPs provide product-specific challenges for fill-finish. Each product is considered carefully at Symbiosis and processes are adapted as required to meet the needs and objectives of each client. Symbiosis supports clients through development, clinical and product approval phases.

Dedicated facility for development and cGMP manufacturing of your advanced therapy medicinal products (ATMPs), including adeno-associated virus (AAV) vectors for gene therapy and gene-modified cell therapy Experts in small-scale commercial Many target markets for ATMPs are for orphan indications, meaning that their small batch sizes can be challenging for larger-scale manufacturers to handle.

>150 mL ≤50L

≤3000 vial

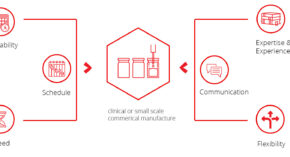

Symbiosis are the leading fast access CDMO for clinical or small scale commercial manufacture and our offering is built upon the following principles:

Waiting 6 or even 12 months for a filling slot can be detrimental. We work to your schedule and strive to have availability in as little as 8 weeks.

Delivering your product to the clinic on time is essential, given patients are often waiting. Therefore, we execute over 90% of projects within the agreed timeframe.

We understand the need for results is a critical factor in the progression of clinical trials. Our typical fill-finish campaign takes 12 weeks.

Our dedicated team has handled >600 filling campaigns for mAbs to more challenging ATMPs for >100 customers. You are in safe hands.

Our service is underpinned by our expert project management team who will keep you informed every step of the way.

Drug development and manufacturing occurs in a dynamic environment. We work flexibly, where possible, to accommodate any changes that you may require.